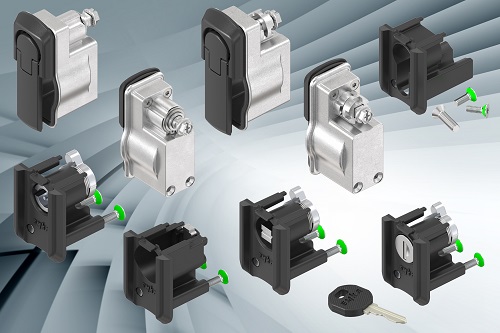

The advanced design of this new lock program is made possible in a mini package (with 70x25mm cut out) by EMKA’s advanced hardware technology, incorporating a flat external design which stands only 9mm above the door so that it can be used in a wide variety of space critical applications. Whether as a closure for wall panels in railway vehicles, as a HotSpot cover on telecommunication housings, as a closure on waste bin housings or on electric charging columns, and much more. Its flat design and magnetically retained swinghandle makes it ideal for areas with narrow passageways, in escape routes or for design-oriented enclosures.

In this new patented design customers are enabled to loosen the two lower screws on the rear side, so the locking set can be pulled out from the front and replaced. If required, other standard inserts, such as the push button from the 2225-U57, can also be implemented. Alternately, on request, the swinghandle without compression function can also be combined with a multi-point locking system.

Due to its compact design, the swinghandle with compression function is smaller than all other existing compression locks on the market in combination with a DIN or KABA cylinder but still offers a full 6mm compression. In addition, this compression latch can be locked and unlocked with all locking devices, including the small EK 333 key, which is not otherwise possible with conventional compression latches, as the keys are usually too weak and can break. The pre-assembled swinghandle and dish feature an integrated scratch protection to prevent surface damage.

Further information on EMKA products can be found on the EMKA website - www.emka.com. Readers can find the latest information and news on the EMKA blog – www.emkablog.co.uk or follow them on twitter - http://twitter.com/emkauk.